A portable water tank from a VCU public-private partnership is designed to transform cancer radiation therapy

William Song, a professor in the School of Medicine, and his partners hope to take a complex, costly process in cancer care and make it faster, more affordable and more accessible.

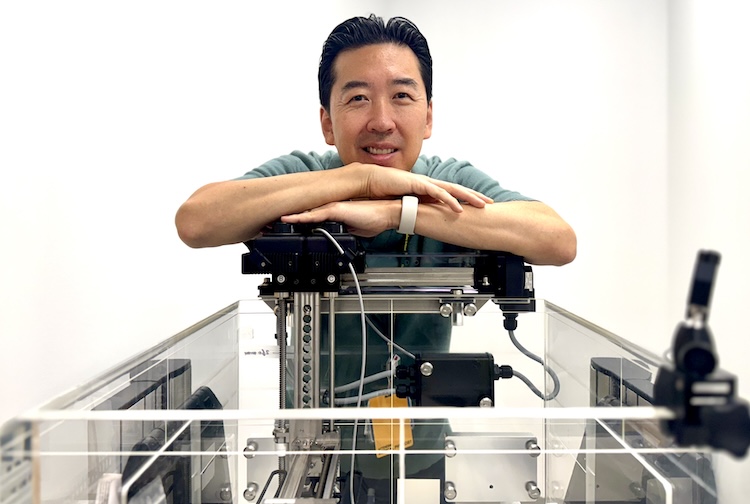

August 14, 2025 William Song, Ph.D., is leading the development of a new portable, foldable water tank used in radiation therapy.(Photo by Jeff Kelley)

William Song, Ph.D., is leading the development of a new portable, foldable water tank used in radiation therapy.(Photo by Jeff Kelley)

By Jeff Kelley

Roughly the size of a large fish tank but far more complex, the water tank “phantom” is an unsung hero in cancer treatment — and a Virginia Commonwealth University medical physicist thinks it’s time to make it smarter, lighter and easier to move.

William Song, Ph.D., professor of radiation oncology and director of the Medical Physics Graduate Program in the School of Medicine and the Department of Radiation Oncology at Massey Comprehensive Cancer Center, is leading the development of a new portable, foldable water tank used in radiation therapy. The innovation has the potential to make cancer care more efficient, affordable and accessible.

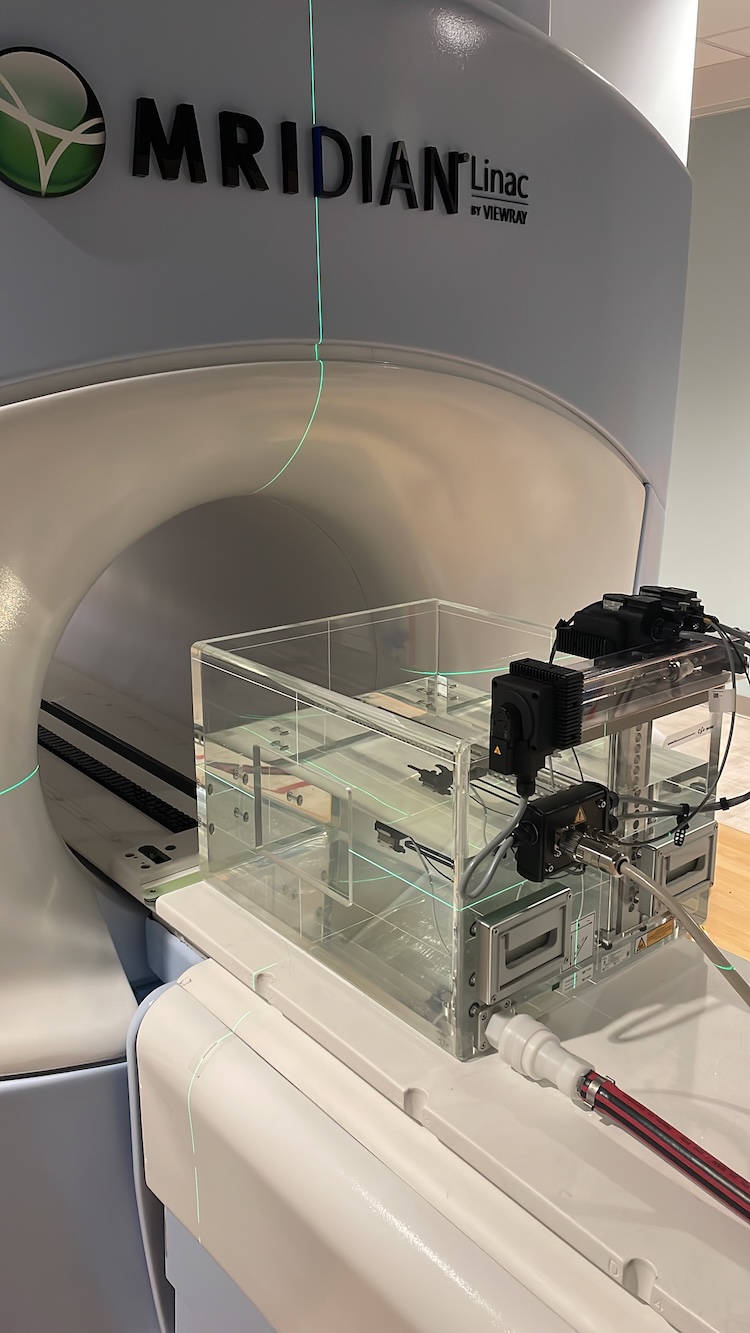

When filled with water, the tank mimics human tissue to measure and verify the radiation dose from cancer treatment machines called medical linear accelerators, or LINACs. The accelerators treat cancerous tumors, and the tank, which sits under a LINAC, measures the dose and shape of the invisible beams — critical to ensuring patient safety and therapy dosage.

“It’s like buying a new car. You need to test the brakes, and learn the car and keep it tuned,” Song said. “And every LINAC machine, even if it’s the same model, performs a little differently.”

Commissioning a new LINAC is the process of calibrating the radiation output for patient safety. It takes up to several weeks and requires specialized equipment at each LINAC location. Essential to the process are the tank and the radiation detectors within it. The tanks are traditionally rigid, heavy and cost upwards of $250,000. LINACs are calibrated at least annually, monitored regularly and adjusted frequently. Transporting a bulky tank between clinics requires movers and costs over $2,000 per move, Song says.

“Tanks have gotten bigger and more sophisticated, but not more portable,” Song said. “And that’s a problem if you’re trying to reach patients through satellite clinics or in rural settings.”

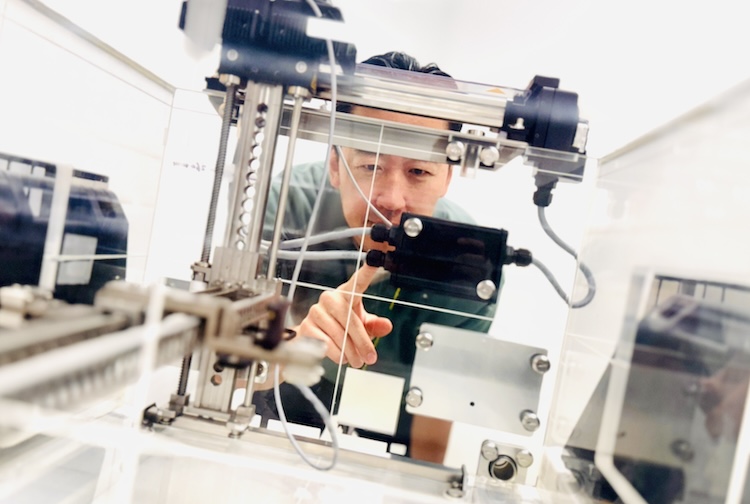

Which led to a question: What if he could make a portable water tank, while improving the quality and speed of the radiation detectors within?

“We realized that if we could make the water tank portable that it could solve a major problem in how hospitals manage and calibrate these machines,” Song said. “We’re not discovering new science — we’re improving the tools. Advancement doesn’t mean more complexity. We want to make things simple and portable so that it can be used in a wide, economical and accessible manner.”

A partnership to improve the process

Florida-based Blue Physics Inc. is a startup developing plastic scintillators — detectors that glow when struck by radiation — that are used in LINAC water tanks for commissioning and quality assurance. Building his startup by demonstrating the scintillators’ speed and accuracy to researchers nationwide, Blue Physics founder and theoretical physicist Marcos Feijoo met Song at a conference of medical physicists.

Song’s interest was piqued by Feijoo’s scintillators, realizing they’d be perfect in a more portable tank. Such a device could be shared and transported between clinics more easily, while maintaining safety standards. Portability could also help vendors demo or test new radiation machines at clinics without slogging around huge tanks.

A collaboration took shape. Song leads design of the phantom and testing, while Feijoo provides the embedded detector technology and software.

Together, they filed a joint patent through VCU TechTransfer and Ventures and secured grant funding through the Office of the Vice President for Research and Innovation’s Commercialization Fund to build the tank prototype.

“As VCU’s research profile has increased in recent years, it is gratifying to see the impact of

the efforts in Central Virginia being recognized not only in our growth of federal research funding, but within private industry, where entrepreneurs seek out our faculty and their ideas to build new innovations,” said P. Srirama Rao, Ph.D., VCU vice president for research and innovation. The National Science Foundation classifies VCU as one of the country's top 50 public universities for research expenditures, surpassing $500 million in 2024.

Song hopes the new tank will dramatically reduce the time and cost required for commissioning and routine quality assurance. “You cannot have a new LINAC sit idle for weeks,” Song said. “This tank could cut that downtime from up to a few weeks to a day.”

For Feijoo, who spent 18 years working for a LINAC manufacturer before founding Blue Physics, the project represents a much-needed modernization in radiation QA.

“The way we measure radiation today is pretty much the same way we measured radiation 50 years ago,” he said. “It was clear to me that this was getting obsolete.”

A market opportunity for a public-private partnership

The U.S. market for linear accelerators was valued at approximately $1.03 billion in 2024 and is projected to grow at a rate of about 6% annually, according to Cognitive Market Research. That positions the nation as a key player within the global LINAC market, estimated at upwards of $5 billion. The demand, perhaps unfortunately, is driven by rising cancer incidence but also the growing use of advanced medical technologies like image-guided and adaptive therapies and continued investment in oncology infrastructure.

“What William and his team are doing is exactly the kind of innovation we aim to support — taking a complex, costly process in cancer care and making it faster, more affordable and more accessible,” said Brent Fagg, assistant director for innovation at VCU TechTransfer and Ventures.

William Song, Ph.D., said his research developing a portable water tank is motivated by cancer patients and desire to limit any delays in their treatment. (Photo by Jeff Kelley)

The project has garnered interest from major academic institutions and private companies, as well as international partners in Japan, Italy and others. Song has partnered with the VCU College of Engineering to develop the prototype tank and its components, which has become a capstone project for mechanical engineering students. Song estimates that a production model could cost less than $50,000 — up to one-fifth the price of traditional tanks — with performance that meets or exceeds international standards for radiation dosimetry.

“Their portable phantom improves on existing technology without rewriting it entirely, making it easier for potential buyers to sign on as customers,” Fagg adds. “This has the potential to reshape how hospitals around the world commission and maintain LINAC machines, and we’re proud to help move that technology from concept to clinic.”

But Song and Feijoo’s mission is broader than simply building a portable tank.

“Our vision is not to offer the tools; it is to offer the solution,” Song said. “This will allow clinics worldwide to deliver better, higher quality treatments to their patients.”

And for Song, it’s not just work — it’s personal.

“What motivates me are the patients,” he said. “Every day a machine is offline is a day someone’s cancer treatment is delayed. My wife was a recent patient of radiation therapy at VCU, so this hits home for me. If we can fix that, we can improve care not just here at VCU [Massey Comprehensive Cancer Center], but everywhere.”

Learn more about our innovative researchers and their projects